opyngpt “In the context of a commercial kitchen, outline the steps in packaging food into containers for storage, and then storing those items as inventory to be delivered to individual restaurants.”Packaging and storing food in a commercial kitchen involves several critical steps to ensure the safety, quality, and efficiency of the process. Here’s a general outline of the steps involved:

1. Preparation

Before packaging, the food must be prepared according to the restaurant’s recipes and standards. This includes cooking, cooling, and portioning the food.

2. Cleaning and Sanitizing Containers

- Clean: All containers used for packaging should be thoroughly cleaned to remove any residue from previous use.

- Sanitize: After cleaning, sanitize the containers to kill any bacteria or pathogens that might be present.

3. Packaging Food

- Portion Control: Ensure each container is filled with the correct amount of food as per the recipe requirements.

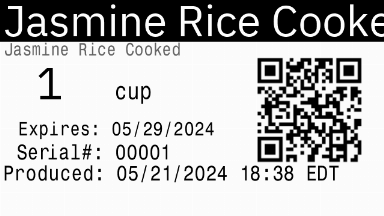

- Labeling: Each container should be clearly labeled with the type of food, date of preparation, and any other relevant information such as allergens or special instructions.

- Sealing: Seal the containers properly to maintain freshness and prevent contamination.

4. Inventory Management

- Inventory Count: Before packaging begins, conduct an inventory count to know what needs to be packaged and stored.

- Tracking: Use a system (manual or digital) to track what has been packaged and stored. This helps in managing stock levels and ensuring nothing is lost or misplaced.

- Storage: Store the packaged food in a designated area following proper temperature control measures to maintain its quality until delivery.

5. Delivery Preparation

- Organization: Organize the containers for easy loading onto delivery vehicles. This could involve grouping them by destination restaurant or type of food.

- Temperature Control: Ensure that all food items are kept at the appropriate temperature during transport to maintain their quality and safety.

6. Delivery

- Route Planning: Plan the delivery route efficiently to minimize travel time and ensure timely delivery.

- Delivery Documentation: Prepare and attach delivery documents to each shipment, including details like recipient address, type of food, and any specific delivery instructions.

7. Post-Delivery Follow-Up

- Feedback: Collect feedback from the receiving restaurants about the condition and quality of the delivered food.

- Replenishment: Based on the feedback and inventory levels, plan for replenishing stocks accordingly.

8. Continuous Improvement

- Review Process: Regularly review the packaging and delivery processes to identify areas for improvement.

- Training: Provide training to staff on best practices for packaging, storage, and delivery to ensure consistency and quality.

This outline provides a comprehensive approach to packaging and storing food in a commercial kitchen before delivering it to individual restaurants. It emphasizes the importance of cleanliness, organization, and adherence to food safety regulations throughout the entire process.

Leave a Reply